Oct 13, 2011 , by

Public Summary Month 9/2011

In the current reporting period we finished Task 1, Task 2 and Task 3. So, regarding to Task 1, we developed a concept for integration of sensor-system and the KUKA LWR wherein we have focused on communication and software interfaces. We have described a concept of an experimental technical framework, analyzed available communication interfaces and discussed their fitness for the individual communication tasks.

In Task 2 the project participants identified three different approaches to calculate the robot workspace which has to be supervised. Additionally we worked out typical use cases and identified those use cases which pose interesting challenges for the EXECELL system.

In Task 3 we finished the workspace setup by mounting required sensors like cameras and projector, mirror and additional equipment on the carrier and bring them into service. The collaborative workbench equipped with the KUKA LWR was placed under the carrier and thus completing the setup as seen in Figure 1.

Figure 1: Entire workspace setup consisting of system carrier, 4 cameras, projector and mirror, workbench with KUKA LWR and integrated controller, and additional hardware equipment.

Aug 9, 2011 , by

Public Summary Month 7/2011

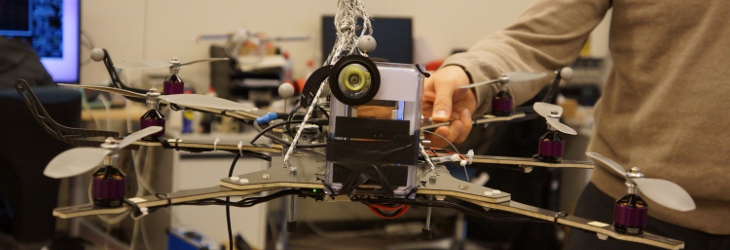

The EXECELL project started with a kick-off meeting of both participants, KUKA and Fraunhofer Institute for Factory Operation and Automation (IFF), at the IFF in Magdeburg. The meeting was used to clarify and define the technical specifications and interface definitions of the system, which are currently being further developed and refined in close-cooperation between the project participants. Furthermore, the project participant KUKA has identified use cases, which are derived from real industrial applications. On basis of that it has begun to identify potential failure modes and analyzing their effects. As seen in Figure 1, we also have begun to set up the workspace by building up a sensor system carrier. Furthermore, we mounted the KUKA LWR 4+ on a moveable workbench, as depicted in Figure 2.

Figure 1: senor-system carrier

Figure 2: KUKA LWR 4+ mounted on moveable workbench with integrated robot controller